An industrial tool magazine machine makes gadgets work better every day. It keeps the tools clean and in order. Each tool has a specific function. Every tool’s location is known to the machine. Tool changes are managed delicately and carefully. Every stop is exact and reliable thanks to reliable indexing technology. It doesn’t shake and action is always correct. This boosts the machine’s reliability. Details and agility are essential in today’s workplaces.

Both needs are jointly fulfilled by a solid CNC machine tool magazine. It reduces the intervals among tasks. The user has less worry as a result. It keeps devices clean, safe, and working. This aids organizations in fulfilling tasks on time. It also aids in keeping each part’s high quality.

Importance of Stable Indexing

When indexing is stable, the tool magazine always stops at the right area. It doesn’t go very far. It doesn’t end early. All of the stops are genuine. This improves the cutting tool’s exact match with the spindle. Every job’s cut quality is improved. Also, it shields the rotor from harm.

Part wear is reduced by a steady system. When switching tools, it reduces noise. A strong machine tool magazine is essential to the day-to-day operations of many manufacturers. From daylight to night, it always delivers an exact outcome. It makes it easier for employees to have belief in the tools.

Built for the Real Factory World

Factories are busy and demanding places to work. There is dust in the air. The heat runs all day. Machines work for long hours. A tool magazine machine is built for real life. It uses strong metal parts. It uses smooth guides for motion. It works again and again without fail. Readers of machine tools world magazine often search for machines that last many years. This solution meets that need well. It is simple to use. It is strong in build. It stays reliable even under pressure.

How a Tool Magazine Works in CNC Systems

A tool magazine in a CNC machine stores many tools in a small and bright space. The CNC control tells the system which tool is needed next. The magazine glides smoothly. An arm, disc, or chain brings the tool forward. Stable indexing locks the tool in place. This smooth process saves time on every cycle. It reduces human error. Operators do not need to frequently touch tools. Many shops depend on this system to meet short delivery times and high order demand.

Types of Tool Magazines Used in CNC Machines

The type of tool magazines used in CNC machines are made for different work needs. Each type has its own use and benefit. Choosing the right one helps the machine work better.

- Drum type magazine for small and compact tool magazine machines

- Chain type magazine for large tool numbers

- Disc type magazine for fast and short tool change

- Arm type magazine for heavy and long tools

Each design supports a different workflow. The right choice improves speed, safety, and output quality.

Designed with Engineering Care

Good machines always start with good planning. A tool magazine adheres to clear design principles. Balance is important. Strength is important. Smooth motion is essential. These ideas are often shared in the machine tool design magazine across the industry. The final system feels simple to use. But inside, it is smart. Every part works together in a clean and controlled way.

Smooth Tool Change for Better Results

Fast tool change saves small bits of time. Over the course of a day, this time becomes substantial. A stable tool magazine reduces wait time between steps. It keeps the production line moving without delay. This is why many machine tool magazines talk about stable indexing systems. They help make clean cuts. They help repeat the same quality again and again.

Supporting the Growing Tool Market

The demand for intelligent machines is growing rapidly. The Machine Tool Market Magazine often shares this growth news. Shops want more speed. They want better quality. They want fewer mistakes. Tool magazine machines answer all these needs. They work well in small shops. They also work well in large factories. They support growth at every level.

Advanced Technology Made Simple

Modern tool magazines use smart sensors and controls. They check the tool position. They check the tool load. They stop errors before they happen. This topic is often covered in the machine tool technology magazine. Even with advanced features, the system stays easy to use. Buttons are clear. Screens are simple. New users learn quickly without stress.

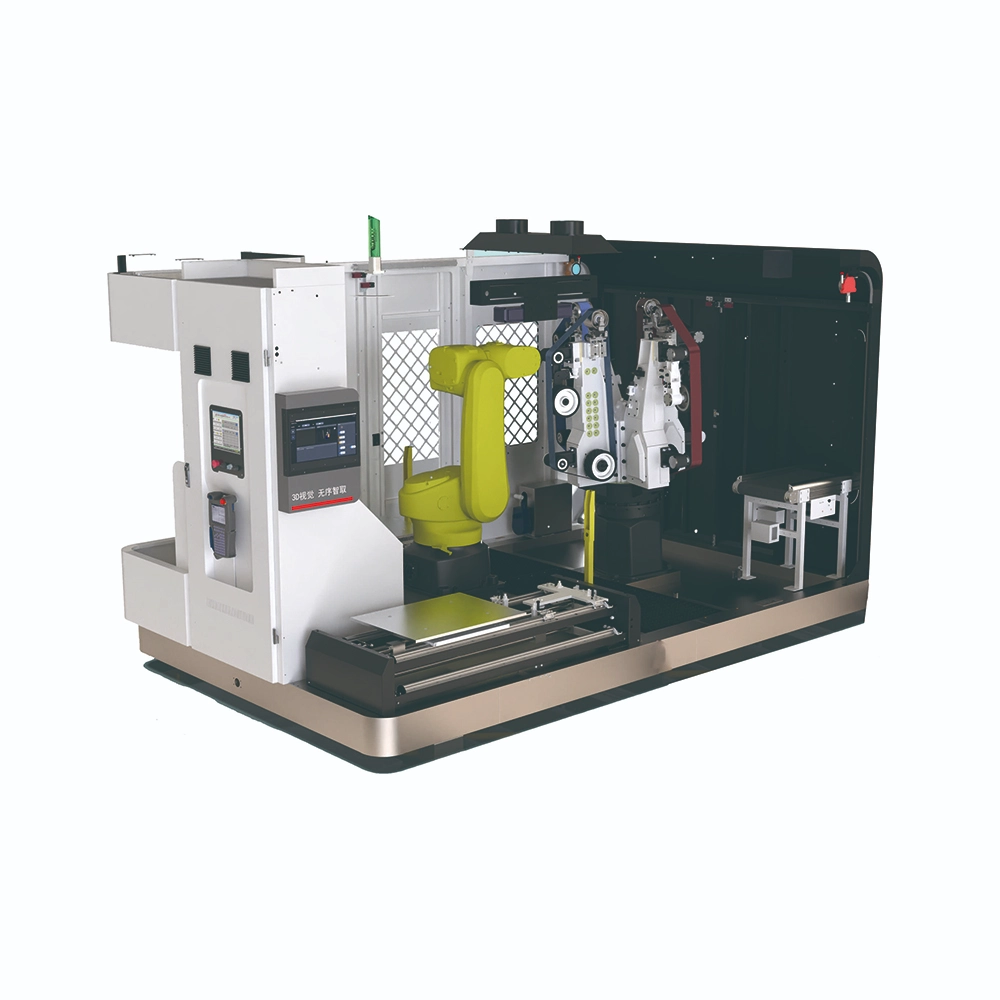

LRMC-800T: Compact Power with Stable Indexing

The LRMC-800T is designed for medium-duty work. It fits nicely in small and tight spaces. It offers a smooth and quiet tool change. Stable indexing ensures that every tool is aligned correctly.

It is simple to install. It is easy to operate. It is ideal for shops that want to grow step by step without high cost.

Key benefits:

- Strong and durable body design

- Smooth and low-noise movement

- Accurate and reliable tool position

- Low maintenance and easy service

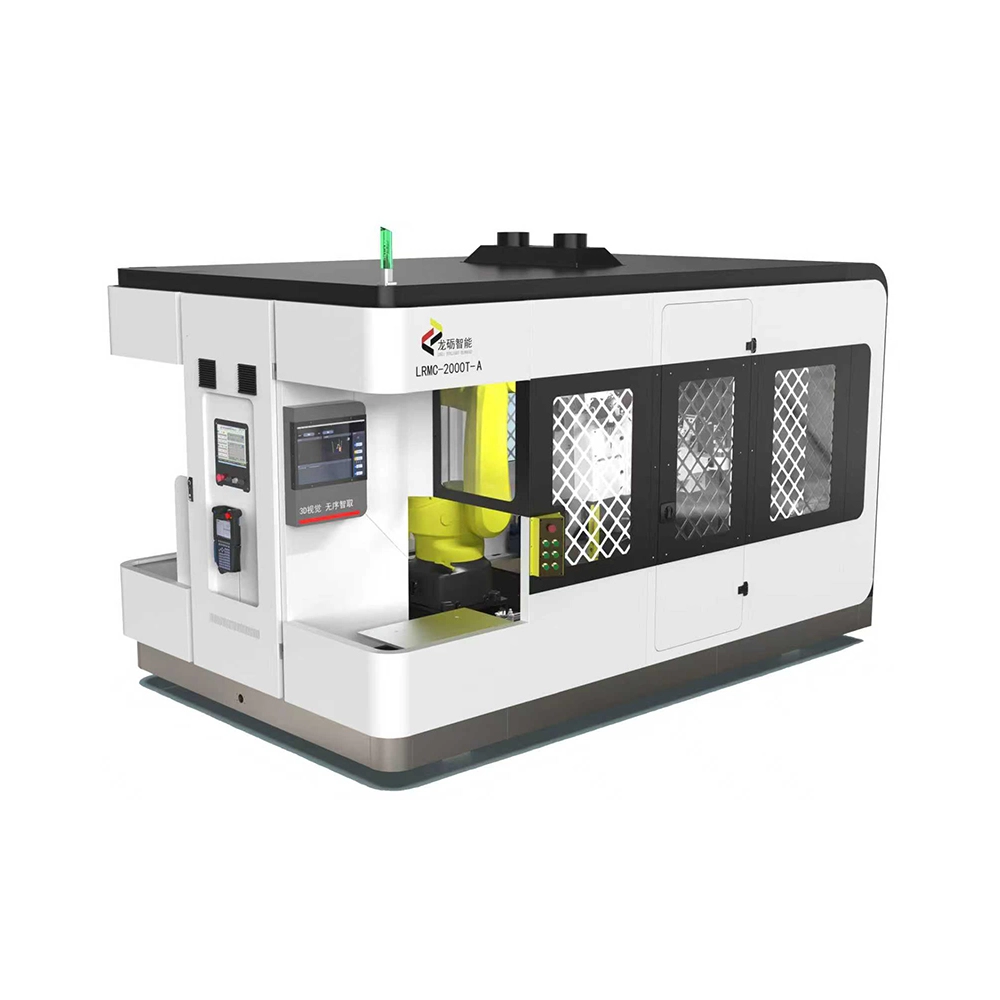

LRMC-2000T-A: High Capacity for Heavy Work

The LRMC-2000T-A is built for heavy-duty and large jobs. It can store more tools. It can carry heavier loads. Stable indexing stays accurate even at high working speed.

This model fits advanced production lines. It supports long working hours. It reduces machine downtime and boosts productivity.

Key benefits:

- Large tool storage capacity

- High strength for heavy tools

- Fast and stable indexing system

- Designed for nonstop factory work

Compare the: Tool Magazine Machine

| Feature | LRMC-800T | LRMC-2000T-A |

| Tool Capacity | Medium | High |

| Space Need | Compact | Larger |

| Load Handling | Standard | Heavy |

| Best Use | Small to mid shops | Large factories |

Select LongLi for the Exact Reliability

LongLi is renowned for producing high-quality machines. Their designs focus on the real needs of factories. Their support team is reliable and helpful. They care about long Tool Magazine Machine life. They show precise product details. It shares real solutions. It helps buyers choose the right machine with ease.

FAQs

- What is a tool magazine machine?

It is a system that stores tools and changes them automatically inside a machine.

- Why is stable indexing important?

It maintains the correct tool position every time. It reduces wear and machine errors.

- Are these machines complicated to use?

No. The controls are simple. Training time is short and easy.

- Which model should I choose?

Choose the LRMC-800T for small to medium-sized needs. Choose LRMC-2000T-A for heavy and high-volume work.

- Where can I buy or learn more?

You can visit the LongLi website to see full details and get support.