Vibration grinding machines are used by businesses every day to make things with flat surfaces and exact shapes. It moves things in a steady way by vibrating all the time. This constant motion slowly and safely grinds away sharp edges. As a result, the look of each part is better. All surfaces are clean and shiny. The finish feels silky smooth when you touch it. The motion’s stability makes sure that the results are the same from batch to batch. This is an easy way to keep quality under control.

Importances of Consistency in Grinding

You always get the same great result when you are consistent. This is very important for grinding jobs. A Vibration Grinding Machine keeps the motion stable and balanced. All the parts fit together perfectly. The medium grinds every surface of the part. We cover every square inch. This helps keep fragile areas or uneven surfaces from happening.

Grinding evenly saves both time and money. It helps reduce waste in the production process. Because of this, there is less rework. Workers spend less time fixing mistakes. Fewer stops make machines work better. These benefits are why a lot of businesses use vibration grinding systems. They believe the results. They trust that the quality will be the same each time.

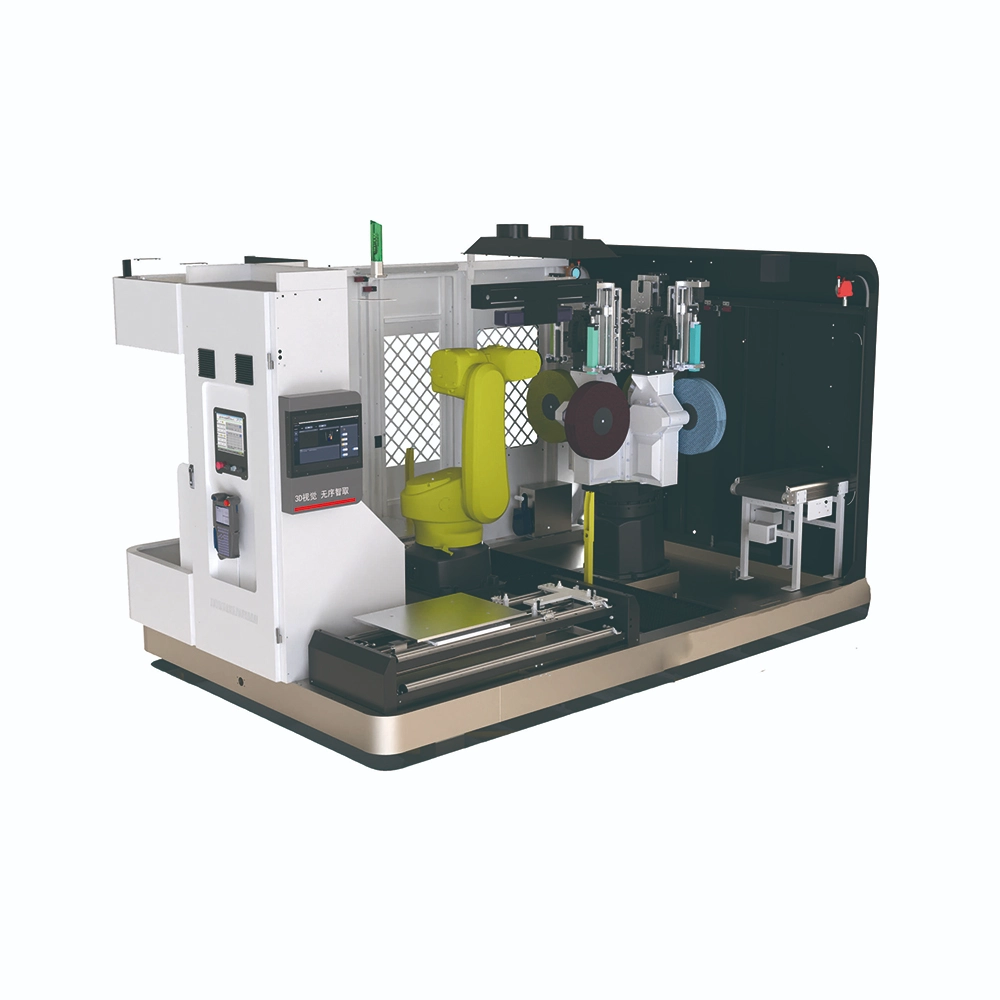

Working Process of Vibration Grinding Machine

A vibration polishing and grinding machine has a strong motor and a strong bowl or tub. The engine makes the vibration happen quickly. The body of the machine vibrates evenly. The bowl or tub shakes in a controlled way that is very smooth. The parts inside the basin move around gently. They grind against the media from every angle.

The process slowly smooths and grinds the surface of each part. You can control friction with water and a certain chemical. They keep the parts cool. Other than that, they are good for dusting. As time goes on, the surface gets cleaner and shinier. Gets a smooth finish. Shapes are kept safe and accurate. The method is gentle, but it works very well.

Key Benefits of Using a Vibrating Grinder

There are many clear benefits to using a vibrating grinder in factories and workshops. It raises the standard. You save work. Also, it makes things easier for operators.

- A perfect surface on all sides of all parts

- All batches have the same quality of surface.

- Less physical work and grinding

- Can handle parts of different sizes

- Very easy to clean and handle

Because the process is automated, employees can focus on other things. More work gets done. The product’s value goes up. Overall, efficiency gets better.

Industrial Use & Applications

Many industries around the world depend on industrial vibration grinding machines. It is common in metal processing plants. It helps companies that make car parts. Tool and hardware makers can use it to make their products look cleaner.

It can help make jewelry, fasteners, and electronic parts. This method can be used in any field that needs smooth transitions. Some of the materials that can be processed well are steel, aluminum, brass, and others. It can easily handle heavy parts. It won’t hurt soft fabrics.

Energy Efficiency & Low Noise Design

Vibration machines use less energy these days. They use smart motors that always give the same output. These motors need less power for long runs. They never get too hot while they work. This makes the motor last longer. There is also very little noise in the background. The tremor isn’t very loud and isn’t too bad. This makes the workplace safer. Workers are less tired. It’s easier to work long hours. A peaceful workplace makes it easier to set priorities and feel safe.

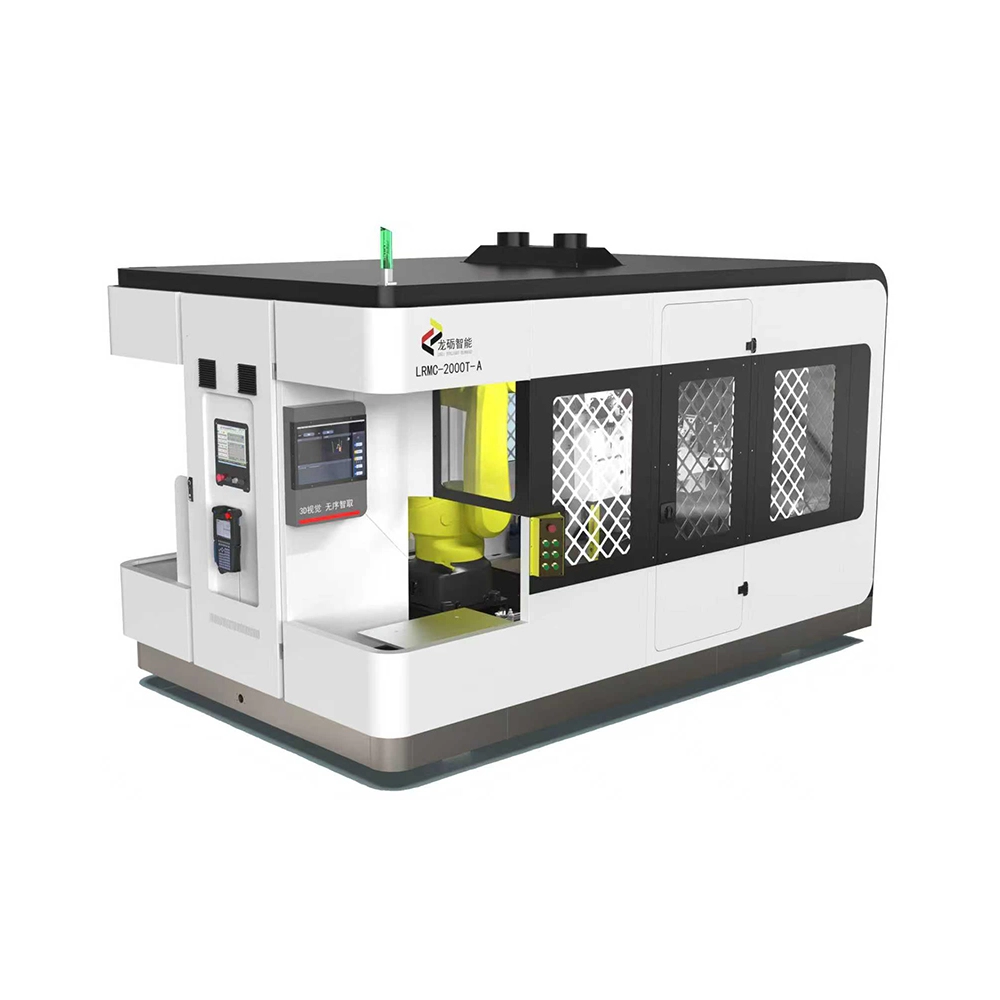

LRMC-2000T-A: Built for Stable Performance

The LRMC-2000T-A is made to be both strong and stable. It handles heavy loads with ease. The vibration stays the same when you run. This makes sure that all the parts have the same level of polish on their surfaces. It works well with medium to large batches. It can run for a long time without any problems. The building is strong. There won’t be many repairs needed. Because of this, it is a great choice for factories that are running.

Best Uses

- Cleaning metal

- Making the surface smooth

- Polishing in groups

Many factories use this method for their everyday manufacturing tasks.

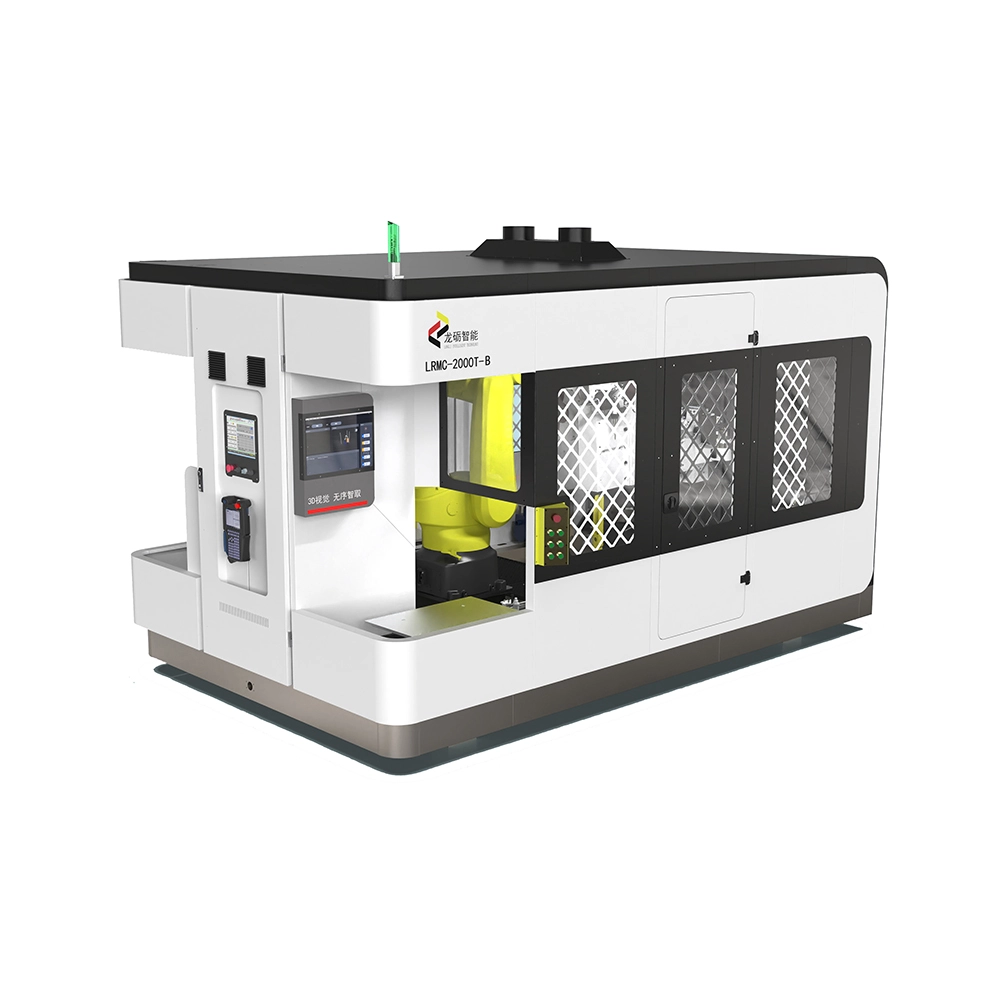

LRMC-2000T-B: Designed for High Output

The design of the LRMC-2000T-B puts both speed and control first. Users can easily change how strong the vibrations are. You can better take care of sensitive areas with this. It makes processing cycles happen quickly. It can work with a lot of different kinds of products. Even as we speed up, we keep the same level of quality. The model has a good balance of power and accuracy.

Best Uses

- Correct parts

- Very fine smoothing

- Mixes of different materials

This model is great for production facilities that need to be quick and careful at the same time.

Vibration Grinding Machine Price Factors

There are a lot of things that can affect the price of a vibration grinding machine. The size of the machine is very important. The power of the motor also affects the price. The design and the quality of the build are both very important. Extra features make things more valuable. A longer life means lower costs over time. Choosing the right size and model can save you money in the long run. A good machine is more than just a cost; it’s an investment.

Comparing the Vibration Grinding Machines

| Feature | LRMC-2000T-A | LRMC-2000T-B |

| Load Capacity | High | Medium to High |

| Control Level | Standard | Advanced |

| Best For | Heavy batches | Precision work |

| Energy Use | Efficient | Very efficient |

Maintenance Made Easy

Daily maintenance is simple and quick. Operators clean the bowl after use. They check the media condition. Bolts and mounts are inspected regularly.

Good maintenance keeps Vibration stable. It extends machine life. It reduces sudden breakdowns. Proper care protects your investment and keeps production smooth.

Most Reliable Site for Vibration Grinding Machines

LongLi is known for reliable machine design. The company focuses on safety and performance. Each machine is tested for stability and long life. The LongLi website provides full product details. It offers technical support. It helps buyers choose the best solution for their needs. LongLi machines are built to deliver steady results.

A good Industrial vibration grinding machine delivers steady quality every day. It reduces manual work. It saves time and cost. Choosing the right model is important. With LongLi machines, consistency becomes simple and reliable.

FAQs

- What is a Vibration grinding machine used for?

A vibration grinding machine is used to grind, smooth, and polish parts. It removes sharp edges and improves surface quality safely.

- Is a vibration grinder machine safe?

Yes, a vibration grinder machine is very safe. It works in a closed system. Noise and dust are low. Operator risk is reduced.

- Can one machine do grinding and polishing?

Yes, a vibration grinding and polishing machine can do both tasks. Users only change the media and compound to switch processes.

- Which model is better for heavy work?

The LRMC-2000T-A is best suited for large, heavy batches. The LRMC-2000T-B is better for fine and fast work.