Modern factories that work well depend on speed to get things done every day. They need to always be accurate. They also need to be able to control things in a smart and simple way. A smart tool magazine machine is perfect for all of these things. It keeps blades and shears safe. It makes sure that all the tools are in the right place. It changes tools very quickly while you work. This makes machines work better. For a long time, production stays steady and doesn’t stop. Workers don’t have to work as hard anymore.

This method also eases the stress on workers. Operators don’t need to stop machines very often. They don’t need sharp tools to get in touch with each other often. A lot of industries now depend on this system for their daily production. The CNC machine tool magazine already has a strong base of modern automation. It lets machines work for long periods of time. Less laziness. The end result is a better product.

Basic Definition of a Tool Magazine Machine

A tool magazine machine is a smart way to store tools. It can talk to CNC machines directly. It has enough space to neatly store a lot of tools. All of the tools are in their right places. The machine chooses the right tool on its own. Here is how it works: it’s quick, easy, and safe. You don’t have to change tools by hand when you work.

The tool magazine in a CNC machine makes the whole process much better. It helps to keep tools apart. It makes it less likely that users will make mistakes. This is how tools stay clean and safe. Tools last longer when you don’t have to handle them as much. This helps businesses save money over time. It also keeps workers safe from sprains and other injuries. It makes the workplace better and more relaxing.

Value of Smart Tool Magazines in these Days

Automation is growing quickly all over the world. Smart tool magazine machines are a must-have these days. You can’t live without them now. Control software and sensors are used by an intelligent tool magazine. It keeps track of how often tools are used. We check the life of the tools in a systematic way. Before their tools wear out, operators are warned.

This smart control makes it possible to plan work better. Every job gets done on time. Machine stops are no longer common. A lot of professionals talk about this in the magazines Machine Tools and Machine Tool Design. The focus is on better output quality. Their downtime numbers are lower. These systems help with lean production methods. They also help factories meet tight delivery deadlines.

Key Benefits of Smart Tool Magazine Systems

- Switching tools quickly

- Tool rack with plenty of space and flexibility

- Cutting down on physical work while improving control over the life of tools

- Robotic process that works well

- Every cycle has a high level of accuracy.

These benefits are frequently discussed in articles in machine tools world magazine. Find out from the experts how smart tools can make manufacturing more efficient. They also show how better planning can help you make more money. You save more money when you waste less. If the process goes faster, more orders will be delivered on time.

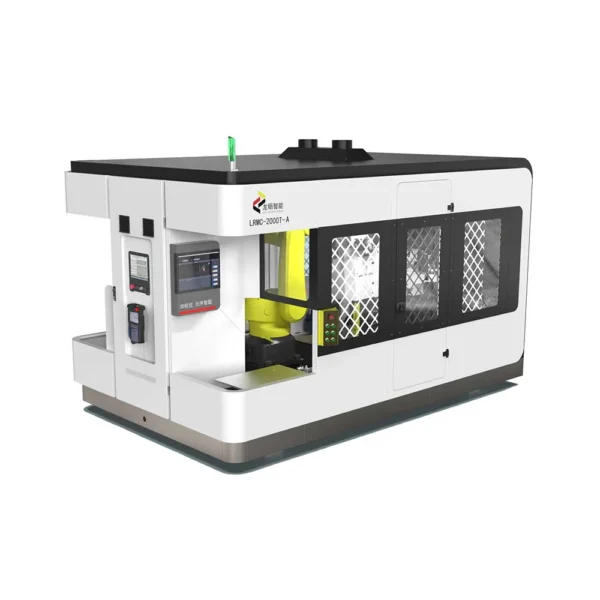

LRMC-2000T-A: Built for Heavy Automation

The LRMC-2000T-A is the best and most powerful solution out there. With its design, production could be large and ongoing. It works with a lot of tools at the same time. It works perfectly with the most up-to-date CNC control technologies. This model has a strong frame. It stays the same no matter how many hours you work.

This equipment is perfect for factories that work at high speeds. It handles difficult tasks with ease. It can handle long production cycles. This model is featured in the machine tool market magazine, which gets a lot of people to buy it. It is known for lasting a long time. Also, it doesn’t need much care. This lowers costs over time.

Features of LRMC-2000T-A

- A lot of space for storing tools

- Changing tools quickly and easily

- A strong and long-lasting frame setup

- It’s easy to understand how to control the system.

- There is some soft background noise and moving water.

This method makes it possible to have the most advanced smart factories. With its help, you can easily reach your high output goals. Companies that make cars and metal parts will love it. It also works very well in harsh industrial environments.

LRMC-800T: Compact Yet Powerful

The LRMC-800T takes up less space. But it works great. It is meant to be used in medium-sized factories. It works well in workshops where space is limited. Its small size hides how quickly and steadily it can change tools.

Machine tool magazine reviews frequently praise the model’s size and power. It is a good deal and worth the money. It makes things in a steady and reliable way. It’s easy to set up. It’s easy to learn how the day-to-day works. There isn’t much maintenance to do, and it doesn’t take long.

Features of LRMC-800T

- A small and efficient layout

- Consistent and exact control of tools

- Installation is easy and quick.

- Basic needs for daily maintenance

- Long-lasting and reliable lifespan

This machine works well for small factories and repair shops. It can also help training centers. It’s easy for beginners to learn. People who know what they’re doing can save time and effort.

Smart Design for Better Results

A high-quality tool magazine machine needs to be designed intelligently. It is made of strong, tried-and-true materials. The layout is easy to understand and makes sense. This design helps keep tools from wearing out. It also keeps tools from crashing when you move them.

Design professionals frequently discuss these ideas in the machine tool design magazine. Their top priority is to keep us safe. They focus mostly on the future. A well-planned design cuts down on downtime. It also makes the person and the computer trust each other more.

Role in Modern CNC Production

Today’s CNC machines need to be both fast and accurate. They also need good tool management. A tool magazine can help you with everything you need. It lets devices work all the time. It makes sure that production goes on without a hitch.

The machine tools magazine often has case studies from real factories. Higher production output is demonstrated by these research. Also, the quality of their surfaces has improved. Most CNC systems these days come with tool magazines. Without them, fancy factories can’t stay in business.

| Feature | LRMC-2000T-A | LRMC-800T |

| Tool Capacity | Very High | Medium |

| Machine Size | Large | Compact |

| Automation Level | Advanced | Standard |

| Best Use | Heavy Production | Medium Production |

| Maintenance | Low | Very Low |

Industries That Use Tool Magazine Machines

- Automotive manufacturing plants

- Metal fabrication workshops

- Aerospace component units

- Mold and die-making factories

- CNC job shops and suppliers

These industries are often covered in the machine tool market magazine. They rely on speed, accuracy, and trust. Tool magazine systems help them grow and expand.

Future of Smart Tool Magazines

The future of Tool Magazine Machines is very bright. Smart systems will continue to grow. Tool Magazine Machine will become even more intelligent. They will use AI-based control. They will predict tool wear early. They will plan tool changes automatically. Experts share these trends in machine tools world magazine. They believe automation will shape future factories. Tool magazines will remain at the core of CNC production systems.

Select LongLi Tool Magazine Machines

LongLi is a trusted global brand for Tool Magazine Machines. It offers strong and reliable machines. It delivers smart automation solutions. Their products meet international quality standards. They focus on long-term performance. They also focus on customer support. LongLi machines are used in many countries. They are known for stable operation. They are also known for easy technical support.

FAQs

What is a tool magazine machine?

It is a smart system that stores and changes tools automatically inside CNC machines.

Why is a smart tool magazine important?

It saves time. It lowers errors. It improves production flow and safety.

Which model is better for large factories?

The LRMC-2000T-A is ideal for heavy, large-scale production.

Is LRMC-800T good for small workshops?

Yes. It is compact. It is easy to use. It fits small spaces very well.

Where can I learn more about these machines?

You can visit the official LongLi website to get full details and support.