Fine finishing can make surfaces shiny, clean, and smooth. To do a good job, workers need to be quick, careful, and in charge. A CNC-compatible polishing machine makes everything work together in one smart system. It makes sure that factories and workshops always make clean, smooth, and bright things. With its modern design and easy-to-use controls, this machine improves the quality of surfaces, saves time, and cuts down on labor. It easily polishes metal parts, wheels, rims, and other delicate surfaces. The machine keeps a steady speed and pressure, which makes it less likely for scratches and marks to happen. This could help both small stores and big companies.

Essential Role of Polishing Nowadays

CNC polishing is an important part of modern manufacturing because it meets the three needs of high quality, safe systems, and fast output. A CNC polishing machine is fast and accurate. It keeps the pressure steady and the movement smooth. This helps the surface shine evenly. It also makes blemishes, scrapes, and rough patches softer. Using the equipment for longer periods of time won’t make workers tired or put too much stress on them. We can keep the product’s quality high from start to finish and make fewer mistakes by doing this.

Another way to save energy and cut down on waste is to polish with a CNC machine. The accuracy of each step keeps extra polishing and material loss from happening. Costs go down and raw materials are saved. Workers’ hands are kept away from moving parts that could be dangerous, which makes the job safer. Simple panels and buttons guide you through each step. This makes daily tasks easier, safer, and more efficient, even for new employees.

Key benefits:

- Dependability and speed

- Shiny, clean shine

- Less trash and scraps

- Simple interfaces with clear displays

- Better safety for users

Precision Power for Wheel Finishing

To finish wheels, you need to be careful and precise when you handle them. Even the tiniest mistakes can leave marks or an uneven shine. This problem can be helped by a high-quality CNC polishing machine. It moves steadily and cuts in clean patterns that don’t hurt the wheel. This means that every wheel may look shiny, clean, and brand new. It can help any type of business, from small shops run by families to huge factories. The machine keeps the pressure even, so every edge and curve gets the same amount of attention.

CNC power is also very flexible, which makes it easy for businesses to polish wheels of all shapes and sizes. You can save programs and use them again. Reduce the amount of time and energy you waste. Workers can easily switch jobs without having to set up a long time in advance. This keeps everything running smoothly and quickly, which means more work gets done every day.

Top uses include:

- Aluminum wheel polishing machine is its primary function.

- Machine that polishes the wheels on big rigs

- The Machine for Polishing Wheels

- Polishing Machine for Wheel Rims.

- truck wheel polishing machine

These jobs require strong dexterity, smooth movement, and a light touch. CNC control makes all three perfectly balanced.

Clean Shine with Advanced Control

Today’s CNC polishers have better control systems, sensors, and smart motors. The way these parts work together keeps the force and speed the same. This way, you don’t get any damage to the surface, burn marks, or swirl lines. The end result is a shiny, mirror-like surface. Computer programs carefully plan out each polishing step, making sure that the results are always the same.

With the advanced control, users can also change the pressure and speed for different materials. You can use this to polish surfaces that are made of soft or hard metals or that are mixed. Staff members can save a number of programs to use later on. This keeps the quality high and the time it takes to set up low. It also makes polishing less of a chore, less dangerous, and faster for regular use.

Durable Build for Heavy Work

Heavy lifting and long shifts need strong machines. CNC polishing machines use thick steel and strong parts to be able to handle this kind of force. This design cuts down on noise and vibration. It stays stable even when you move quickly. Strong construction quality means fewer breakdowns and faster repairs. In businesses, this helps keep things running smoothly.

A strong body also protects the internal organs better. As a result, repair costs go down and the life of the machine goes up. A strong framework keeps polishing going all the time. This makes the machine safe and reliable for regular, hard work.

Common choices:

- Prices for aluminum wheel polish machines for small and large shops

- A strong machine will last longer, cost less, and do better work every day.

Smart Automation for Easy Use

Automation makes work easier and faster. CNC systems store a lot of programs for different jobs. With just one click, you can start a whole polishing cycle. New employees can learn quickly because the displays show clear steps. So, the amount of time spent training and the number of mistakes made go down.

Smart automation also keeps productivity up even during long shifts. Sensors are always watching for motion and pressure. That way, you won’t do anything stupid. Workers can focus on staying safe while the machine does the heavy lifting. With this, everyday tasks are simple and stress-free.

The benefits of automation are:

- Easy to set up and quick to start

- New workers can pick things up quickly.

- There must be workers with at least some skills

- Output that is steady all day

Product Highlights from LongLi

LRMC-2000T-B – Heavy-Duty CNC Polishing Solution

The LRMC-2000T-B can handle long shifts, heavy parts, and hard work. It keeps the quality high and can easily handle tough tasks. Its strong construction, powerful motor, and smart CNC control could be useful for big factories. It lets you make things quickly without losing the quality of the finish. Its complex mechanism keeps fluid action going while dampening vibration. This method of polishing big wheels and metal parts makes them look like new. The design cuts down on noise and saves electricity at the same time. When services are easy to get to, getting care is quick and easy.

Key features:

- Powerful engine for tough tasks

- A strong steel frame will keep things stable.

- Smart CNC control that is precise

- Less background noise for a safer place to work

- Easy to take care of

Best for:

- Cars with a lot of wheels

- Tires for big cars and trucks

- Big factories for making things

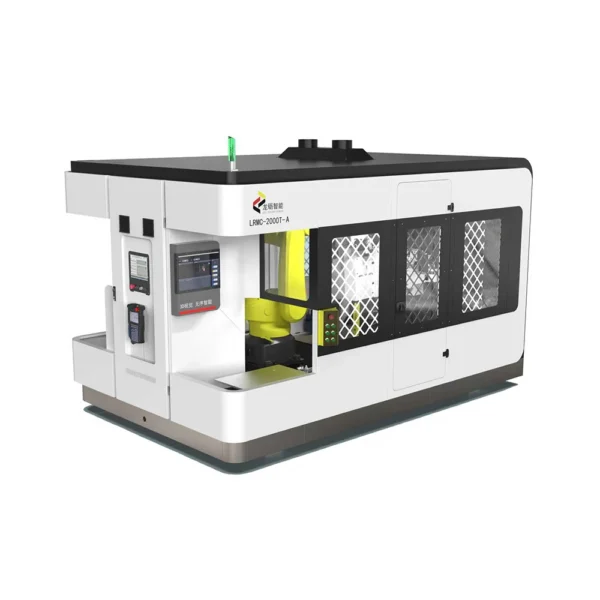

LRMC-2000T-A – Flexible CNC Polisher for Fine Work

The LRMC-2000T-A puts a lot of emphasis on control and accuracy. Small amounts, custom work, and a mix of tasks are all good fits. It is small, which saves space, but it is still very accurate. This machine is great for offices that are small to medium-sized. It has the ability to make quick program changes, use little power, and move smoothly. For new parts, workers can just change the settings. As a result, the time spent waiting is shorter and work goes more smoothly. To keep fragile surfaces safe, you need to be careful with them.

Key features:

- Compact design for small areas

- High accuracy control

- Smooth movement for clean finish

- Energy-saving system

- Quick program change

Best for:

- Small and mid-size workshops

- Custom wheel jobs

- Fine surface polishing

| Feature | LRMC-2000T-B | LRMC-2000T-A |

| Power | Very High | High |

| Frame | Heavy-duty | Compact |

| Control | Advanced CNC | Smart CNC |

| Best Use | Mass production | Custom & mixed jobs |

| Energy Use | Medium | Low |

Leading Brand for Polishing Machines: LongLi

LongLi is a trusted name in the design and production of polishing machines. Their machines focus on quality, safety, ease of use, and long life. Each unit is tested before shipping to ensure good performance. Skilled support teams offer fast help, clear guides, and easy access to spare parts. Their machines are built with care and modern technology. This helps customers get great results with less effort and lower cost. LongLi also provides training, service support, and long-term help.

FAQs

What is a CNC-compatible polishing-machine?

It is a polishing system that uses computer control to move smoothly and apply steady pressure.

Is it good for wheels?

Yes. It is perfect for wheel rim polishing machine and truck wheel polishing machine tasks.

Can small shops use CNC polishers?

Yes. Compact models like LRMC-2000T-A work well in small workshops.

Does CNC polishing save time?

Yes. It speeds up work and reduces rework.

Where can I find reliable machines?

Visit the official LongLi website for trusted machines and support.