Factories need things that are clean, smooth, and brightly colored. This could help them sell more and give their customers better service. A high-quality polishing machine makes this job easier. It helps businesses save time every day. There is also less hard physical work. When machines do the polishing, every product looks the same. This is how quality is kept up. Companies can make more things in less time with modern polishing tools. This also makes things worth more on the market. Companies can keep their high standards without putting in any extra work. In modern manufacturing, machines have mostly taken the place of hand tools.

An Advanced Polishing Machine

A state-of-the-art polish machine is necessary for modern manufacturing. It is strong and can handle rough metal surfaces. It makes results that are bright and smooth without any work. The machines can run for a long time because they have big motors. They also have basic control systems to keep things in check and safe at work. You can polish a lot of things at once. This will help you save time and money on labor.

A metal polishing machine can get rid of rust, scratches, stains, and dull coatings on metal. Polishing makes a surface clean and shiny. After that, the parts could be used or sold. These devices also help reduce waste, which is a nice bonus. You don’t have to polish as many pieces anymore. This is one way that factories can cut costs and improve quality.

Machine Polishing Is Better Than Manual Work

Polishing by hand takes a lot of time and work. The worker’s skill determines what happens. This means that the finish could look different on each piece. When you use machine polishing, the end result is always the same. Everything looks good and nothing seems out of place. Because of this, the quality stays high.

A machine polished surface also keeps its shine for a much longer period of time. It lasts longer and is less likely to get dirty. The shine also lasts longer. This makes the product last longer. People trust products that look polished.

Wheel Polishing Machines for Heavy-Duty Use

Every day, wheels have to deal with heat, dust, and a lot of wear and tear. Be very careful when you polish them. A wheel polishing machine is needed for this job, which takes a lot of time. The shape of the wheel stays the same as it is polished. It gives things a shiny, perfect shine. A wheel polisher machine is an essential tool for cleaning alloy wheels and other car parts. The wheel’s shape and size are safe. The finished wheel looks clean and new. This is especially useful for companies that make cars, motorcycles, and replacement parts.

Aluminum Polishing Made Easy

Aluminum is light and flexible. It could get damaged quickly if you don’t polish it right. An aluminum polishing machine’s job is to carefully polish aluminum. It fixes small flaws and dull spots. It keeps the surface smooth and firm. An aluminum wheel polishing machine can do a good job of polishing wheel rims and alloy wheels. Because of this, they look shiny. Another benefit is that the wheels last a long time. This is very important when making cars and motorcycles. People are more likely to buy aluminum wheels that are clean.

Vibratory Polishing for Small and Bulk Parts

A vibratory polishing machine is great for polishing delicate metal parts. It can polish a lot of things at once. The machine uses vibration and polishing medium to make everything smooth and even. This method saves both time and energy. It makes any rough spots on any part smooth. This is where a lot of small tools like screws, nuts, clips, and others go. It makes the surface better without requiring any extra work.

Key Benefits of Using Advanced Polish Machines

- Fast turnaround time for large orders

- Every time, the finish is perfect and even.

- Less work for employees

- Saving money over time

- Better looks for goods

- The equipment lasts a long time with little care.

These benefits speed up the growth of factories. They also help you meet delivery dates. Machines make everyday tasks easier and more efficient.

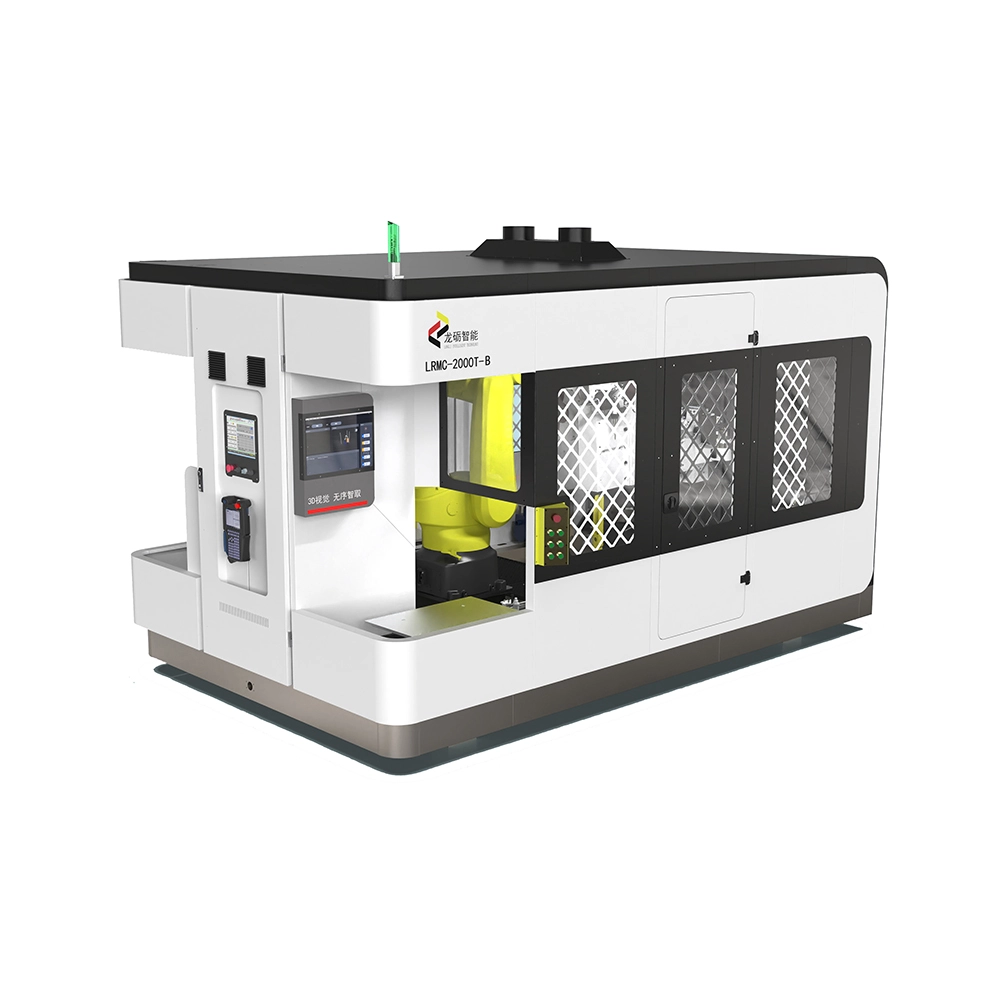

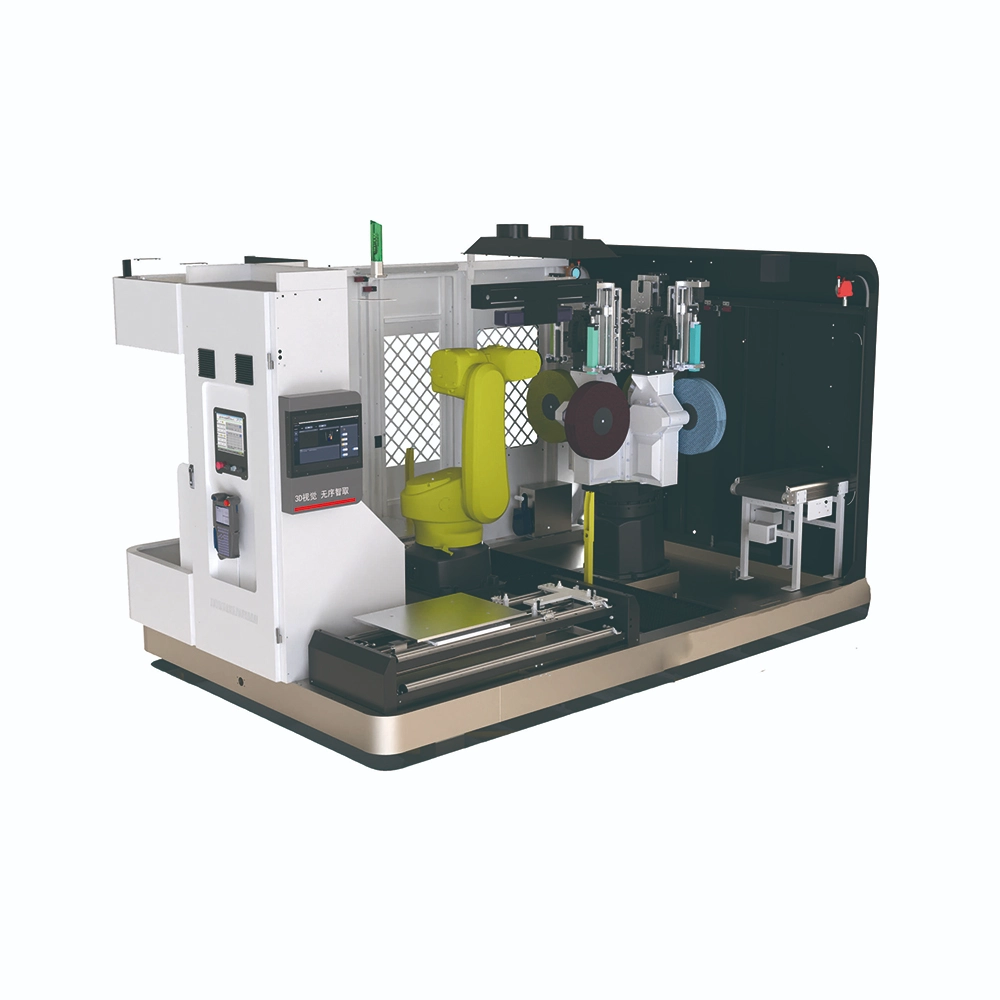

LRMC-2000T-B Polishing Machine

The LRMC-2000T-B is best at doing very hard polishing jobs in factories. The strong construction makes sure it won’t fall over when it’s in use. It works well with a lot of power and fluidity. It stays high quality even after many years of use.

This machine makes it easy to polish wheels and metal parts. The results are always the same and clean. Even people who don’t know much about it can use it. It also doesn’t need much care. So, it’s a good choice for factories and workshops.

LRMC-2000T-B Key Features

- Strong frame that is perfect for everyday use

- A polishing method that works well and is always the same

- A simple way to control

- Makes exact copies of many different metals

- Made to last a long time

This machine will work well in any size workshop. With its help, the daily output goals are met. Its goal is to keep costs down without lowering quality.

Industrial Uses of Polishing Machines

- These devices are used in many different fields, including making cars and car parts.

- Tools and machines made of metal

- Making wheels and rims Tools and hardware

- Things for cooking and the home

In all of these fields, finishing should be easy and perfect. Advanced machines make this job quick and reliable.

How Polishing Improves Product Value

Polished products look and feel more elegant. Customers learn this quickly. Things that are well-made tend to sell faster. People trust things more when they look neat and well-made.

A metal polishing machine or wheel polisher can make brands look more polished. Brings out shine and polish. People are also returning and complaining about products less often.

Easy Maintenance and Long Life

Polishing tools made today are meant to last a long time. With little work, they can stay in good shape. Cleaning and checking are all that is needed for simple maintenance. So, machines break down less often. It also saves money to fix it. If you take good care of the machine, it can run reliably for a long time.

Manual vs Machine Polishing

| Feature | Manual Polishing | Machine Polishing |

| Speed | Slow | Fast |

| Finish | Uneven | Smooth |

| Labor | High | Low |

| Cost Over Time | High | Low |

| Quality Control | Difficult | Easy |

This table shows why machine polishing is better for modern factories.

Choose LongLi Polishing Solutions

LongLi is renowned for producing robust and dependable polishing machines. The company prioritizes safety and ease of use. Each machine is checked for balance, strength, and finish before delivery. The LRMC-2000T-B shows LongLi’s focus on modern factory needs. It helps businesses grow. It also helps control costs over time.

Advanced polishing machines enable factories to work more efficiently and effectively. They save time. They improve product quality. They support steady growth.

FAQs

What is a wheel polishing machine used for?

A wheel polish machine cleans and shines metal wheels. It gives smooth and even results.

Is machine polishing safe for aluminum?

Yes. When used correctly, machine polishing is safe for aluminum parts and wheels.

Can one machine polish many parts at once?

Yes. Vibratory machines can polish multiple small parts in a single cycle.

Why choose an advanced polishing-machine?

These machines work quickly, produce smooth results, and reduce labor costs.

Where can I buy the LRMC-2000T-B?

You can buy or learn more about it on the official LongLi website or from approved sellers.