These days, getting a perfect finish on metal or other stuff in factories is super important. If things are rough or uneven, it can mess up the whole product. That’s where vibratory grinding machines come in! They make surfaces smooth, shiny, and the same all over. Plus, they’re quick, safe, and easy to handle. With all the new tech, these grinders are better than ever at saving factories time and money while giving great results.

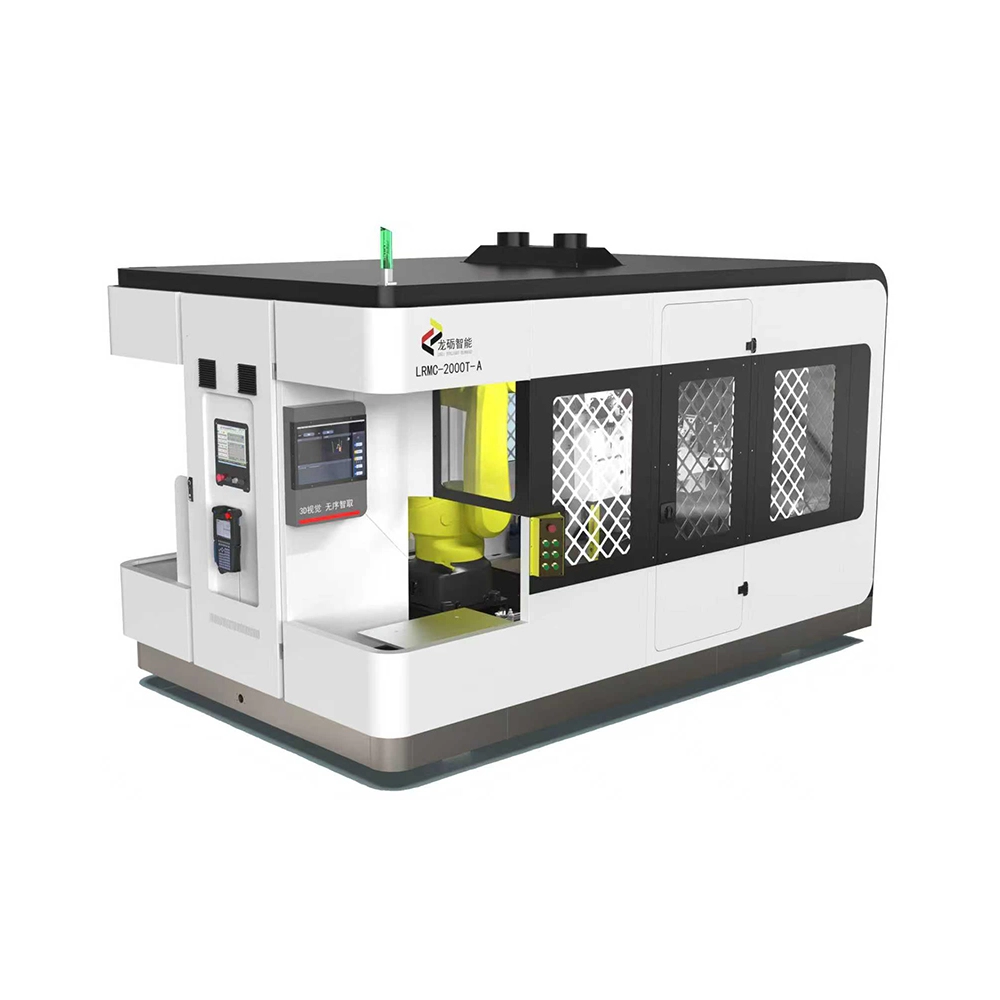

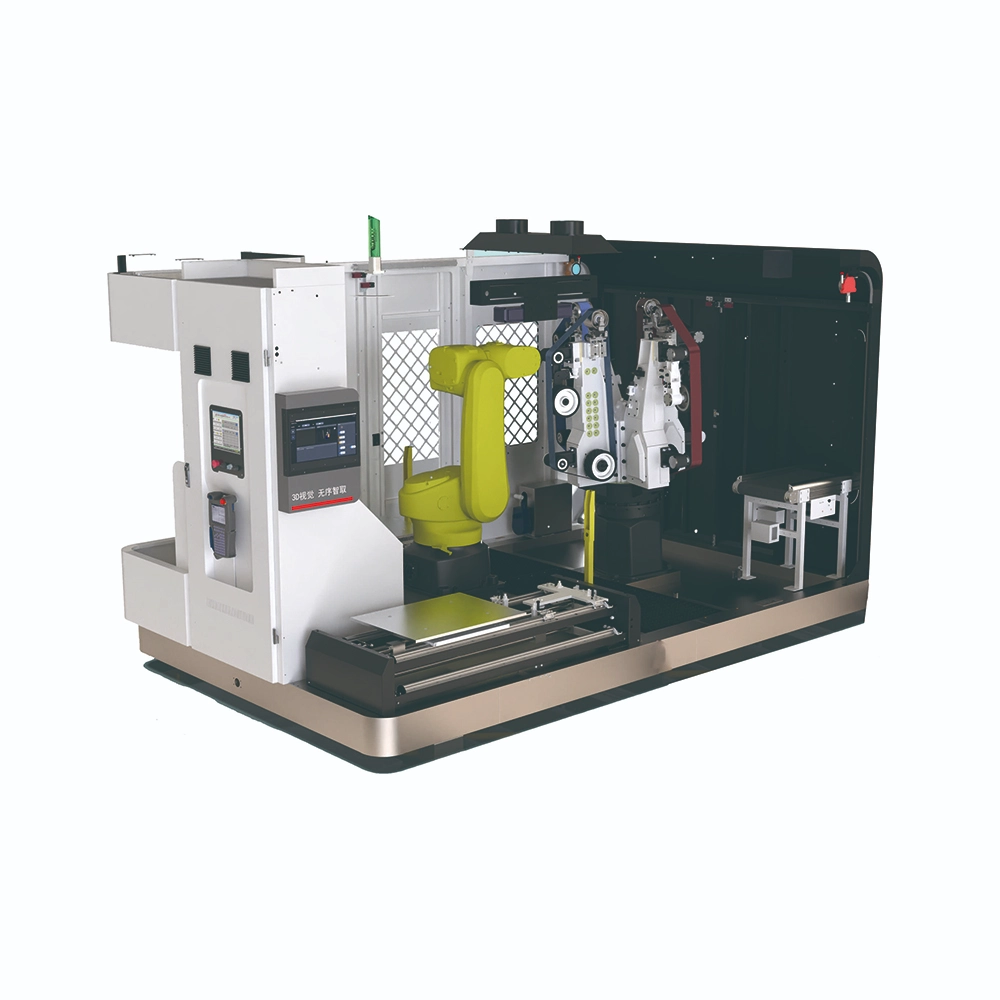

Pro Vibratory Grinding Machine – (LRMC-2000T-A)

This Industrial deburring machine is made to make grinding and polishing simple and spot-on.

It’s got four rotary belt sander tools that get rid of those rough edges on aluminum die-casting pieces. It polishes everything up nicely and accurately, so you get smooth results every single time.

It’s also automated, which helps cut down on labor costs and speed things up. It comes with a Fanuc robot and cool visual detection systems. Workers simply place the parts on the belt, and the robot does everything else, even if all the parts are jumbled together.

Safety and environmental care are also built in. The machine has a strong cast-iron base and an independent room. It includes a hydrogen detector and a dust monitoring system to meet environmental standards.

The LRMC-2000T-A can grind and polish aluminum, zinc, copper, iron, and stainless steel. It is perfect for car parts, bicycle frames, smart door locks, and household lamps.

What is a Vibratory Grinding Machine and How It Works

So, it’s a tool for polishing and smoothing surfaces on metal, plastic or other materials. You place the parts in a bowl or tub with pebbles or ceramic forms. When the machine is on, the bowl shakes. This shaking makes the stones rub against the parts. This rubbing action gets rid of rough edges or extra stuff from the making of the product. The more it shakes, the smoother the surfaces get. It’s gentle, but it has the effect you want, giving finishes that are the same on every surface.

Key Features of Advanced Vibratory Grinding Machines

Newer grinders have a bunch of features that make them stand out. You can change the vibration speeds to work with different materials. Some have timers to control how long things are polished. The bowls can be made of tough steel, rubber, or plastic so they don’t wear out. They often have noise reduction systems, which makes them safer for workers. Also, some models have systems that keep dust from spreading around the factory. These things make sure the machine works well and gives the same results all the time.

Benefits of Metal Polishing Equipment for Smooth Finishing

Factories have all the good things about vibratory grinding.

- It ensures that surfaces are smooth and level. This results in a good-looking final product.

- It is time-efficient because it can process many parts concurrently.

- It eliminates the manual labor that can be backbreaking and unsafe. Workers need not polish every single piece.

- It’s a good reducer of material waste because it can be precise and gentle.

- They make things safer by reducing dust and noise, which is better for workers and the environment.

Different Types of Vibratory Grinding Machines Available

There are distinct types for different requirements. Tub-type machines are standard and can accommodate numerous parts at a time. Inline machines are for making things in series, which is perfect for assembly lines. Rotary vibrators are gentle on sensitive material. Some are even ultrasonic, employing high-frequency vibration to shine on hard things. The right one for you depends on the materials, part size and finish you’d like. They all produce smooth results, just in different ways.

How Vibratory Grinding Ensures Consistent Surface Quality

One reason factories employ such machines is that they do exactly the same thing every single time. I don’t have experience with hand polish, so no comparison there, but the machine works well. The vibration causes the stones to glide on surfaces equally. This prevents them from being lopsided or scuffed. You can also adjust the speed, duration, and intensity of vibrations. By adjusting these settings, you’ll be able to achieve the same quality each time. This is really important in things where details matter, such as cars, planes and electronics.

Materials and Industries Ideal for Vibratory Grinding

It’s great with different materials. It’s a good choice for metals such as steel, aluminum and brass. It also operates on plastics, ceramics and even stone. This makes it helpful everywhere. In car manufacturing, it polishes engine parts and metal bodies. It’s also perfect for cleaning tiny electronic parts. Grinders are also used by jewelry makers to remove excess metal from castings and stamp work, as well as for carving wax for use in making molds. In the production of medical devices, these machines also ensure that tiny parts stay secure and on target. Anywhere that is smooth and even is a priority will realise benefits.

Energy Efficiency and Cost-Effectiveness of Modern Machines

New grinders are made to save energy. They use less power than older ones but work even better. This cuts down on factory costs and helps the planet. Plus, the machines last, so you don’t have to fix or replace them as often. If they don’t break down, you get more done and make more money. Since they can handle lots of parts at once, you don’t have to pay as much for labor. Overall, these automated grinding systems save factories time, money, and energy, so they’re a smart move.

Choosing the Right Vibratory Grinder for Your Needs

Picking the precision finishing equipment relies on your materials, part sizes, and how much you’re making. For small parts and smooth finishes, rotary or ultrasonic grinders might be best. For big jobs, tub-type or inline machines work better. Think about features like vibration speed, noise reduction, and keeping dust down. Make sure the surface finishing machine is made of tough stuff that lasts. Checking these things makes sure you get the best results and save money later on.

Buy Good Vibratory Grinding Machines

If you’re looking for a good place to get these machines, LIRONWORKS is a great bet. They were born from the spark of a grinding wheel. It was started by people who were tired of workers breathing bad dust and factories wasting money on bad quality. LIRONWORKS machines are made for safety, efficiency, and doing the same thing every time. They offer all kinds for different places and price ranges. By picking WIRONWORKS, factories get good equipment that lasts, makes smooth finishes, and keeps workers safe. They care about quality and safety, so they’re great in the grinding world.

Final Thoughts

Cool vibratory grinding machines are changing how factories get smooth and the same finishes. They’re fast, cut down on labor, and make things safer. With different kinds, adjustable settings, and energy-saving designs, these mass finishing machines fit almost any place. Factories that use them save money, waste less, and keep things high-quality. By picking a good company like

LIRONWORKS, everyone makes sure they get equipment they can trust, safe workers, and the same results on everything they make. Aluminum die-cast grinder is a choice that make scene for doing manufacturing now.

FAQs

What is a vibratory grinding machine?

It’s a machine that smooths and polishes parts using shaking and small grinding stones.

What stuff can it work on?

It works on metals, plastics, ceramics, and some rocks.

How does it make sure surfaces are smooth?

The shaking makes the stones rub evenly over every part.

Are vibratory grinders safe for workers?

Yes, new machines cut down on dust and noise to make things safer.

Who makes good vibratory grinding machines?

LIRONWORKS offers safe machines for all industries.