Shine has a warm and inviting feel. When something is shiny, it looks new, clean, and bright. Light can make even the smallest things look amazing. We will show you how to use a brushing shining machine to make dull parts shiny, step by step. No frills or fancy words here. Anyone can read it because the writing is clear and easy to follow. As you follow the brush’s path, you can see the shadows getting lighter, the old marks fading, and each object coming back to life.

Working Process of Brushing Shining Machine

Every surface is polished to a rich, warm shine by this brushing shining machine, which also gets rid of any dull spots. The metal no longer looks weathered. It brings out the wood’s fine grain. It gives little things that need to look neat a new lease on life. It can be used in big companies, small stores, or even a home office. The brush spins and puts a uniform, bright shine on the part. When you touch the part, it feels like it was carefully shaped. With the shine, the object will look better and last longer.

Importance of Brushing Shining Machine

Shine reflects light. It makes the project look more real. It looks like the colourful part was made with care. People feel good when they see a clean and neat finish, which is why shiny parts sell quickly. Adding shine makes your brand stand out more. It’s clear how skilled they are. It shows that work was put into it. Buyers will remember and notice your products more if they have shiny finishes.

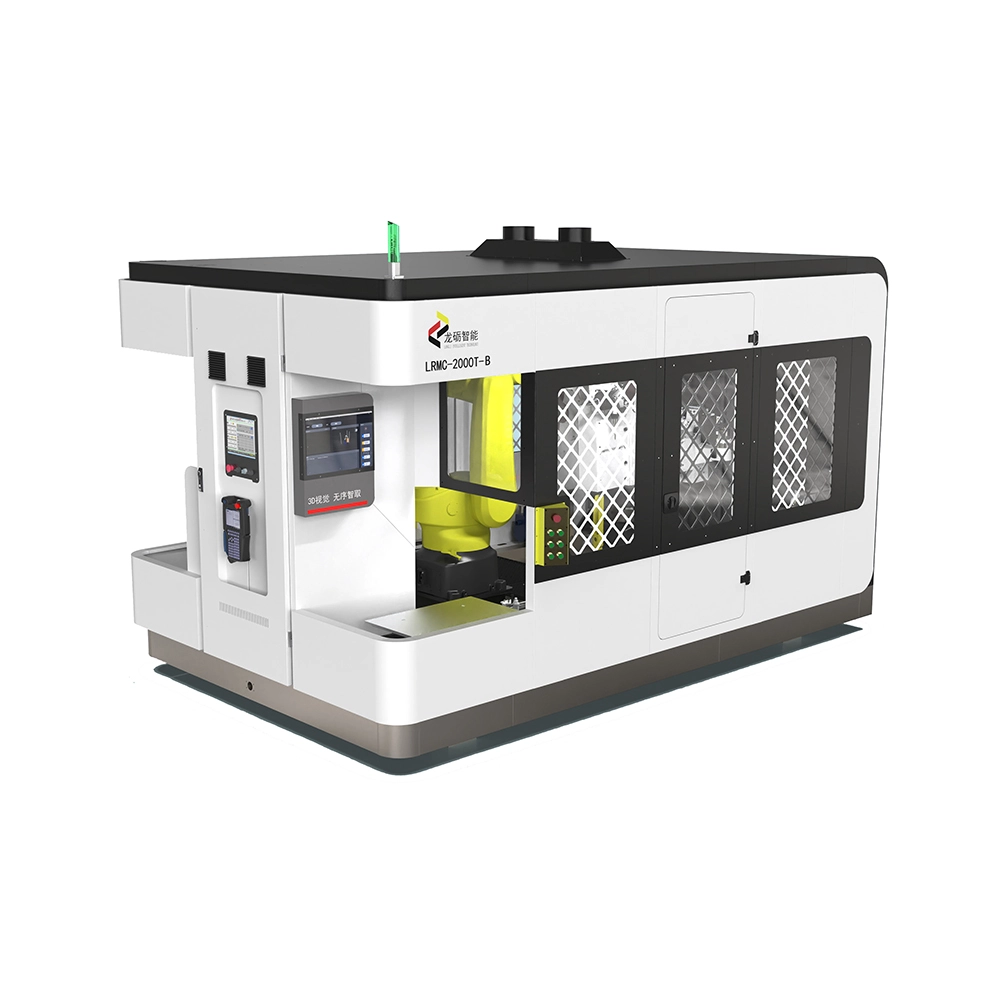

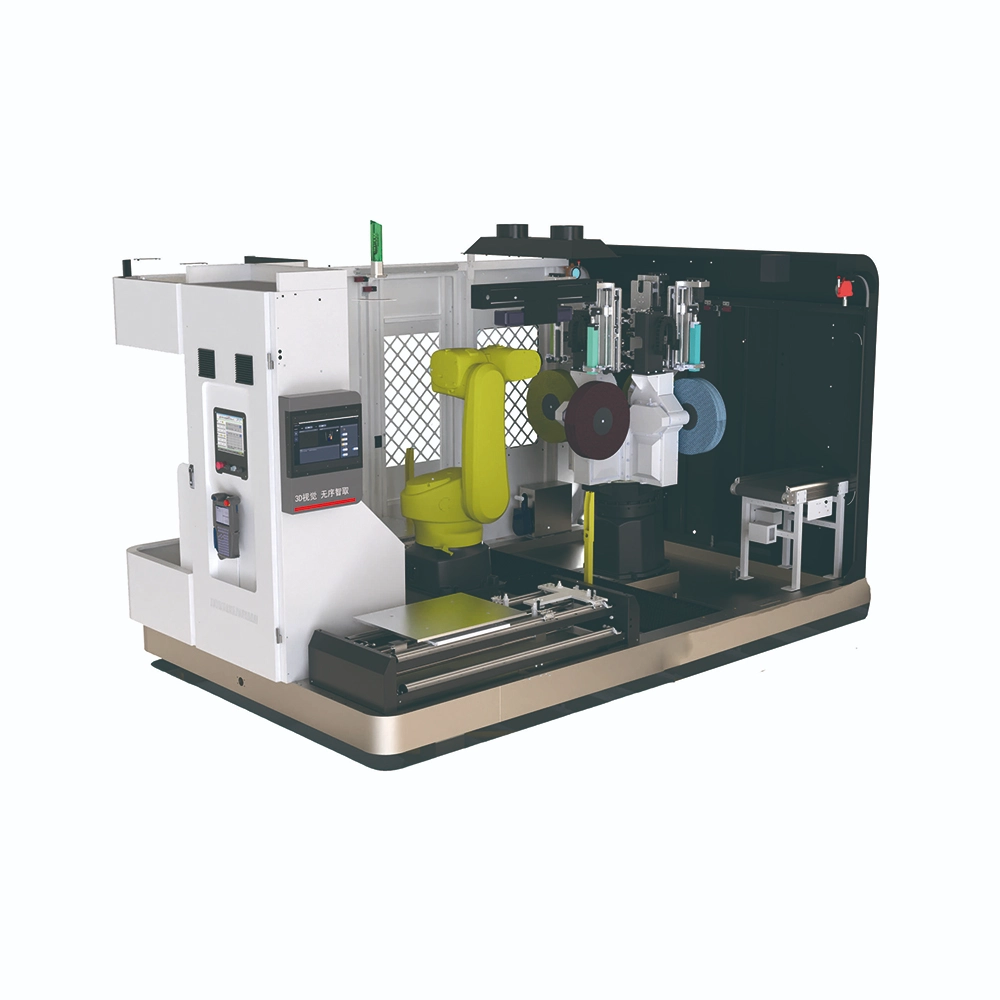

LRMC-2000T-B

This LRMC-2000T-B brushing and shining machine will run quietly and well for years, so you won’t hear a thing. It gives any material, like rods, sheets, and trim, a beautiful shine. Because of this, your job will look better, feel better, and be cleaner.

Working Method:

These brushing machines‘ quickly spinning brush heads sweep and clear the parts. Every spin gets rid of dirt, dust, and small flaws. As you brush the surface, the shine slowly builds up. The part is safe because the heat stays low. The brush evenly spreads light with each stroke because it keeps its shape.

Parts You Can Shine

- Steel plates

- Rods of metal

- Planks of wood

- Parts of the mould

- Cut off extra rods and tubes

The Brush Action

The brush wheels need to pick up tiny dust particles for the part to “breathe” again. They move slowly and carefully so they don’t hurt the part. They can get to places that are hard to reach and find dirt that is hidden. They smooth out rough spots and make sharp corners less sharp. The brush leaves behind a warm light that is almost new. Each fibre spreads the shine evenly across the part.

Tools for Many Tasks

You can polish anything from narrow strips to big sections with a brush like this. They can work with softer materials in addition to metal and wood. A lot of stores like them because you can change the speed for each part. This makes it easy to switch jobs.

Small Shop Use

Smaller shops can benefit from Mini Polishing Machines. It is easy to set up and fits well in small spaces. It easily polishes small parts. It moves slowly and quietly. New employees may learn the ropes quickly and be able to work without problems.

Workflow Steps

- Use the belt or the bed to hold up the part.

- Turn on the brush and let it glide over the surface.

- Change the speed to fit the type of item you’re painting.

- You can change the speed if you think the shine needs it.

- After the part looks shiny and smooth, put it in a box.

It’s easy to follow these steps, even on the first day.

Pick LongLi for Accurate Results

LongLi makes long-lasting brushing and shining tools. Their tools keep parts shiny even after working for several hours. Every machine is tested before it leaves the store. With their help, you can get the right unit. Follow their instructions for taking care of your brushes and using them safely to get a clean, even sheen. They always give you great service that is accurate. They make their devices out of high-quality materials that last a long time.

Brushing shining machine price varies with machine size and power. When working with small parts, miniature machines are more efficient and cost-effective. Larger Polisher Machine units cost more for jobs that need a deeper shine. Before you choose, think about the size of the part and how much shine you need.

FAQ

- Can it shine on soft wood?

Yes. Use soft brushes and a slow speed.

- Is the brushing shining machine safe to use?

Yes. Follow the steps and you will be fine. You can easily use the machine.

- Can a brushing shining machine run all day?

Yes. Just keep it clean and cool. You can easily use it for a long term use.

- Can new users learn fast?

Yes. The steps are short and straightforward.