Technical Support & Training Services

We provide comprehensive technical support and training to ensure you get the most out of our products. Our services include:

- On-site Training:

We offer one week of on-site training at your facility, helping your team become fully familiar with the equipment’s operation, maintenance, and troubleshooting procedures. - Online Video Training:

Remote video training sessions are available for your team, allowing flexible and efficient learning without the need for travel. Our engineers will guide you step-by-step through installation, configuration, and usage. - Remote Machine Debugging:

Our technical experts can remotely connect to your system to diagnose and resolve any operational issues, ensuring your equipment runs smoothly and efficiently. - On-site Service (When Necessary):

If the situation requires, our engineers can visit your location to provide hands-on assistance, including installation, maintenance, and performance optimization.

FAQs

How to handle equipment alarms

Firstly, observe the alarm prompts that appear on the built-in screen of the equipment. After pausing the equipment operation, follow the prompts to find the corresponding location for troubleshooting.

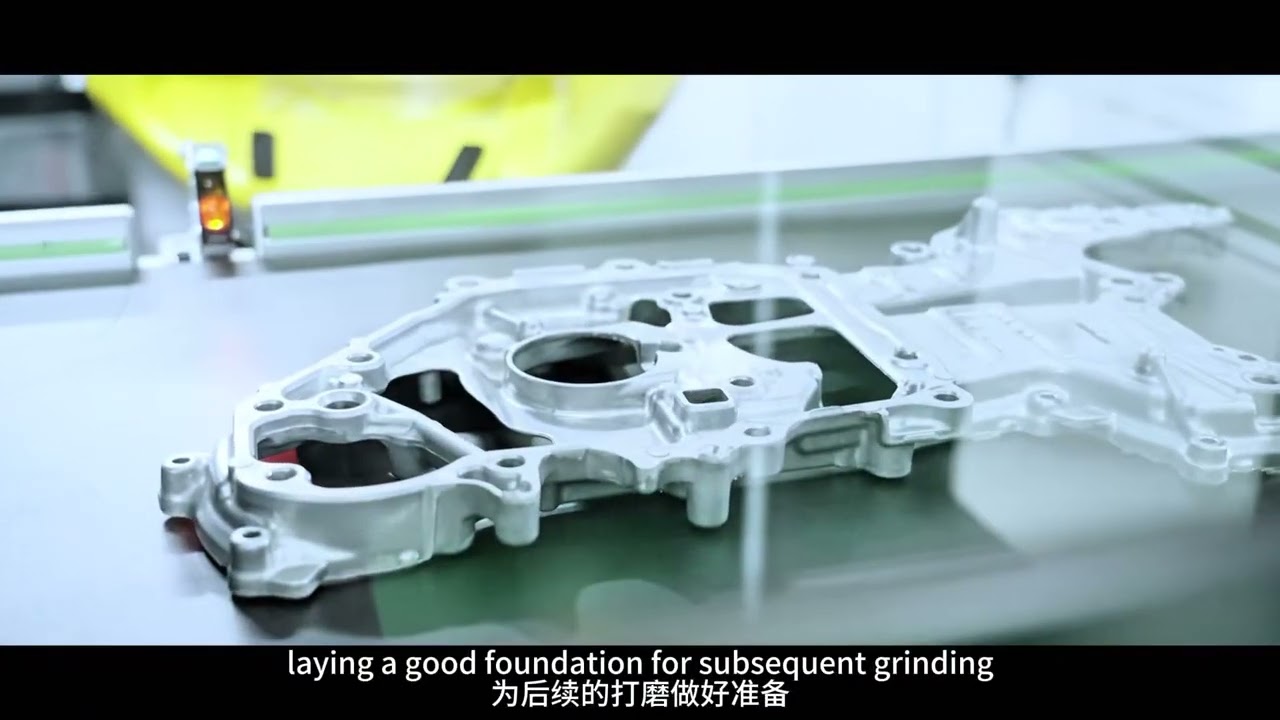

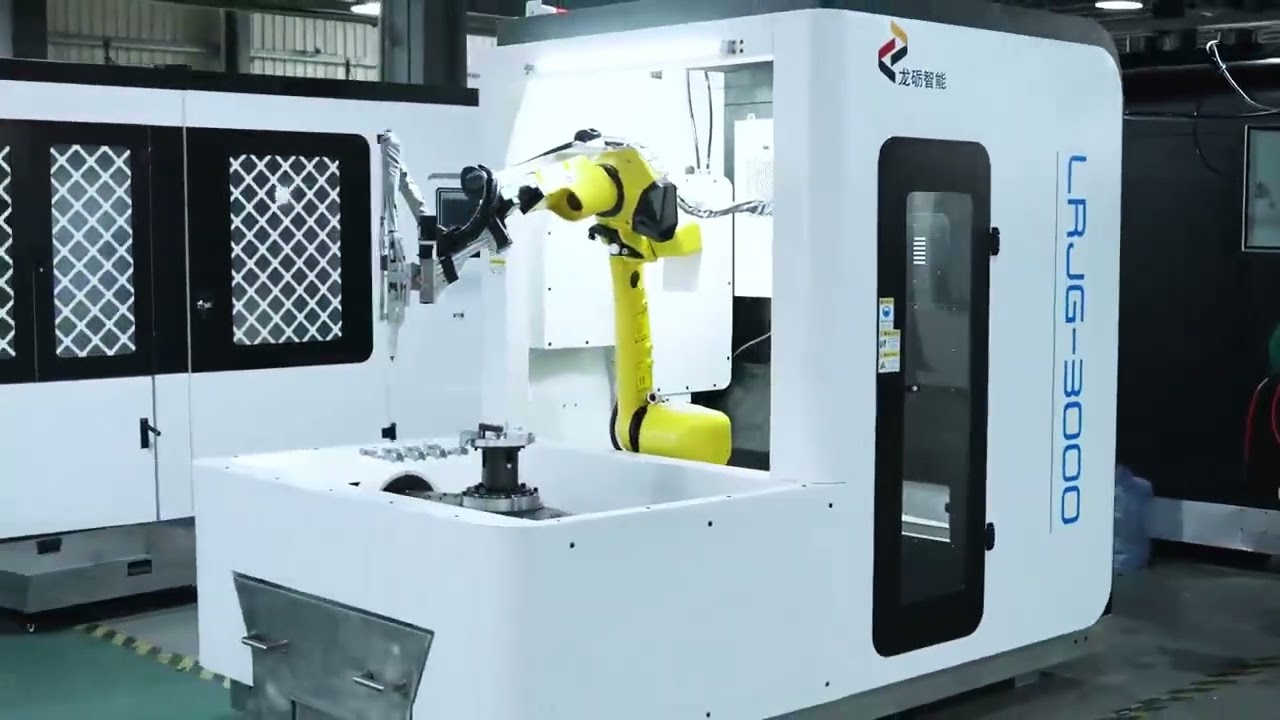

How to Choose a Suitable Grinding and Polishing Workstation for a Product

Quickly locate the grinding and polishing workstation based on the applicable product’s die casting machine tonnage (for example, for a 400 ton die casting machine product, LRMC-400T and other higher tonnage equipment can be selected), perform secondary matching based on the applicable product size parameters, and finally select the appropriate model according to the self generated needs and product process requirements to find a suitable grinding and polishing workstation.

How to deal with the alarm of robot backup battery shortage during use

When the battery level of the robot’s backup battery is low, a prompt will appear on the robot’s teaching pendant. Normal use is not affected at this time, but after the equipment is used, the robot should be kept powered on and our company should be contacted to purchase a dedicated battery in a timely manner. After replacing the robot’s backup battery, the robot can be powered off.

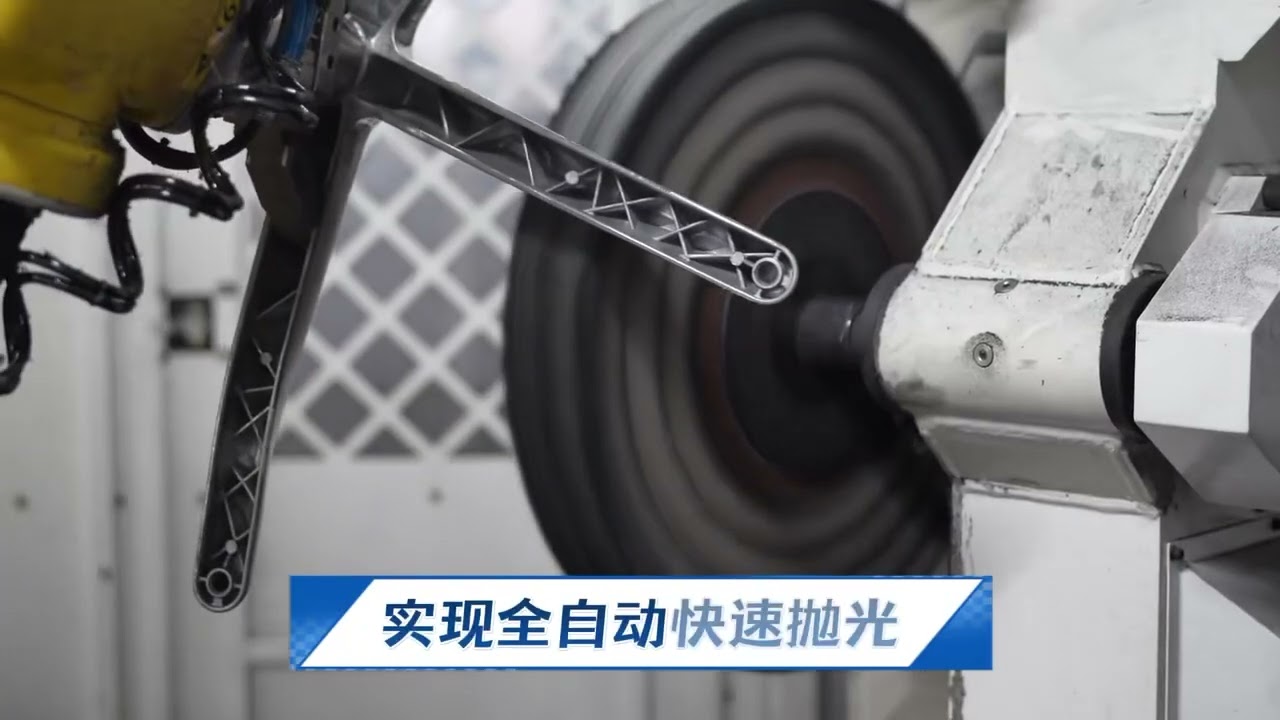

How to replace the sanding belt in the sanding belt machine

After stopping the equipment operation, locate the sand belt tightening control valve on the side of the sand belt machine. After triggering, the sand belt will relax. At this time, replace the corresponding sand belt (note that the direction marked on the sand belt is consistent with the rotation direction of the sand belt machine). After completion, trigger the tightening control valve again, and the position of the sand belt will be automatically corrected during the operation of the sand belt machine.

Video Center

Playlist

1:01

0:17

0:27

0:57

0:29

0:21

Need More Help

Our team is here to assist you—just send us your questions and we’ll get back to you shortly.